In the world of modified cars, few builds walk the line between controversy and admiration quite like Paul Reene’s Ford Escort MkI. At first glance, it may seem like a classic British racer — low-slung, purpose-built, and unapologetically loud. But under the skin, this 1973 Escort harbors a secret that would make purists on both sides of an age-old British rivalry raise their eyebrows. Paul’s Escort is powered not by a Ford mill, but by a Vauxhall heart. In a region where the blue oval of Ford and the Griffin badge of Vauxhall have waged a generational war, this build is an act of defiant unity — and a masterclass in uncompromised engineering.

Beyond Brand Loyalty

It’s easy to fall into automotive tribalism. Whether it’s allegiance to a marque, a style, or a geographic origin, many enthusiasts eventually find themselves aligning with one side of a motoring divide. But these loyalties are rarely innate. They’re shaped by our environments — the friends we hang out with, the local car scene, and the stories we grow up hearing.

Paul Reene chose a different path. Rather than staying in the trenches of the Ford vs. Vauxhall rivalry, he stepped across the battlefield. His Escort, built not just to compete but to dominate, fuses the classic character of a MkI Ford with the high-performance potential of a Vauxhall C20XE engine — and the result is a car that divides opinions but conquers asphalt.

From Restoration to Reinvention

Paul owned the Escort for over a decade before undertaking what would become its ultimate transformation. Earlier stages of the car’s life included a Pinto engine and later a Zetec, but the current setup is no ordinary swap. This build represents a full rethink, a culmination of years of experience and an unwavering vision to create the perfect track car without compromising the essence of the Escort.

To begin, the shell — still in superb condition — was stripped to bare metal. It received extensive seam welding and a fully FIA-compliant T45 steel roll cage. Despite the Escort’s age, not a single patch of rust needed repairing — a rarity that became the foundation of the entire project. The chassis remains largely original, with only small modifications like the removal of part of the inner front wings.

Chasing Lightweight Precision

Paul’s philosophy was clear: add strength where needed and strip away everything else. He was determined to retain the Escort’s soul, avoiding shortcuts like a tube chassis or full space frame. Instead, weight-saving came from smart material choices — fibreglass panels, polycarbonate windows, and minimal interior fittings helped bring the car’s weight down to just 770kg (1,697lb).

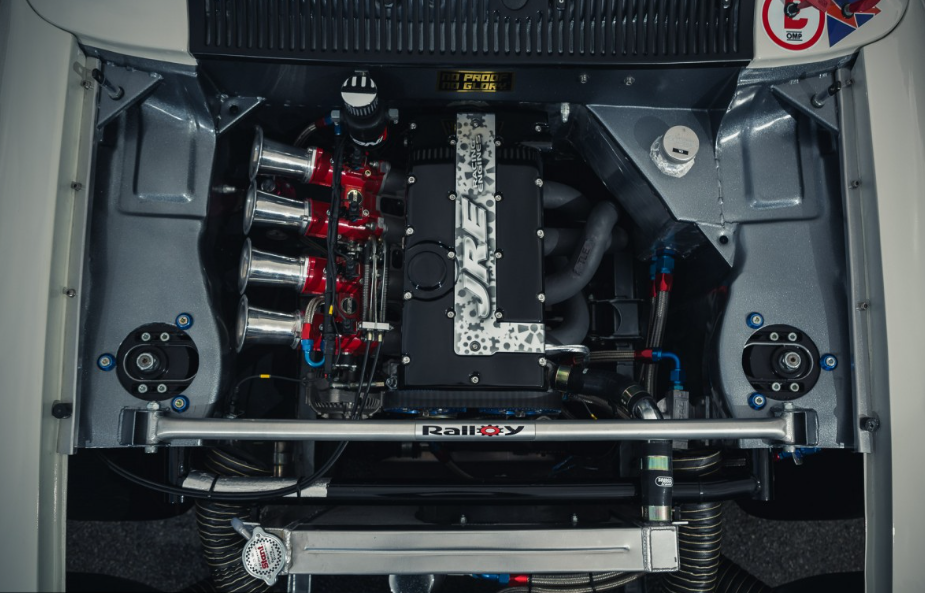

The focus wasn’t only on shedding pounds, but on optimizing where the weight sat. The engine was pushed back 9 inches and dropped nearly 2 inches lower than stock. A reinforced custom bulkhead and a dry sump system made this possible. At the rear, the fuel cell was recessed into the floor, accompanied by a Sytec fuel pump and swirl pot. Every decision was about balance and control.

The Vauxhall Powerplant: Breaking Rules with Logic

While the Vauxhall C20XE might seem like a betrayal to Ford loyalists, it was a decision rooted in practicality and performance. Built by JRE, the naturally aspirated 2.0L engine produces 250hp and 189lb-ft of torque — impressive numbers considering the car’s featherweight frame. The C20XE also holds a peculiar connection to Ford history, having been developed by Cosworth for Vauxhall in the late 1980s.

Paul’s version includes Jenvey 48mm throttle bodies, custom cams, forged internals, and a Tony Law exhaust manifold. The result? A screaming, high-revving unit that delivers over 320hp per ton — more than enough to leave modern performance cars in the dust on a tight track.

Built for the Track, Tuned for Victory

A car like this deserves more than just raw power — it demands a drivetrain and suspension system that can harness it. Paul equipped the Escort with a Quaife 60G six-speed sequential gearbox and flat-shift technology for lightning-fast gear changes. Power is delivered through a custom Fostek English axle and a Tran-X limited-slip differential.

GAZ coilovers on all corners, with remote reservoirs and custom spring rates, keep the Escort planted and agile. Suspension travel is minimal, body roll nearly nonexistent. AP Racing brakes and lightweight Compomotive wheels round out a setup that’s been dialed in for maximum grip and control.

Even the exhaust system was custom-engineered. A short, side-exit pipe snakes through the cabin and exits just behind the passenger door. Not only does this enhance performance and reduce weight, but it delivers an unmistakable bark with every throttle blip and flat-shift.

More Than the Sum of Its Parts

When Paul first put the car through its paces at Tynagh Circuit in County Galway, it wasn’t just a test of machinery — it was the moment of truth. Years of planning, fabrication, and hard decisions led to this point. And the car delivered. With every upshift snap, every high-pitched wail of induction, the Escort proved that Paul’s gamble had paid off.

As the session wrapped up with a celebratory series of donuts — a mechanical ballet of noise and smoke — it was clear that the Escort wasn’t just fast. It was joyful, visceral, and unmistakably personal.

Lessons from the Frontline

Paul’s Escort teaches us more than just how to build a great car. It’s a reminder that loyalty to a brand or tradition shouldn’t limit innovation. Sometimes, the best builds happen when we dare to blur the lines, when we chase performance instead of purity. There will always be critics — but there will also be admiration for those who push boundaries with conviction.

So the next time you’re tempted to dismiss a build for breaking the “rules,” think of Paul Reene and his Escort. Because sometimes, the car that dares to divide is the one that conquers.